Products were designed before we knew better. Material intelligence will transform product design.

Why we invested in MadeFrom

💡 We’ve also open-sourced our research for everyone to see. Check out our latest public Notion page on fashion supply chains here.

Materials matter

Have you ever picked up a pencil and wondered why exactly it was designed in that way?

Probably not. Most objects have been designed around a function, and we don’t tend to think too much about the details. But the pencil offers an interesting insight into how humans think: it’s one of the many objects that has changed materials more than it has changed form.

At the end of the 16th century, charcoal was switched to graphite because of "the ability to re-draw on top of it with ink”. Before the pencil eraser was developed in 1858, people in the 16th century were using household bread to erase pencil marks. The pencil design hasn’t changed much, but the materials have. As we get smarter and discover new things, we change the materials we use.

And now they need to change again.

So far, we have designed products optimising for price and availability, and around material properties like durability. We have only recently realised the huge impact that the materials we use have on the environment. We now need to add another data point: how much is this material impacting the future of our planet? We need to build products for a low-carbon world.

Fashion’s footprint

Let’s take fashion. More than 70% of the fashion industry’s emissions come from the production and processing of the materials alone. It’s generally price and speed that’s optimised, meaning fast fashion has turned to cheap and speedy-to-make synthetic fibers (in less than ten years synthetics are estimated to be 73% of all fiber production). These synthetic fibres end up in landfill after just seven or eight uses, despite the 48 million tonnes of crude oil poured into their production each year, and taking up to hundreds of years to decompose.

New fashion companies are springing up to offer alternative production methods - but it’s hard to tell the difference between the greenwashers and those who are actually redesigning the clothing process for a better world. As an example, making clothes or shoes out of plastic bottles can seem like an attractive alternative - promising to save plastic bottles from landfill right. But in fact using bottles for clothing permanently takes plastic bottles out of their closed loop recycling system. PET bottles can be recycled into PET bottles many times, but once turned into clothes they are a "one-way ticket to landfill”.

Employees need to be empowered to have an impact

Lots of people who work in industries like fashion are realising they need to (and want to) work towards sustainable practices. They want to move towards better materials and low carbon business models. The question is how. Even with the best intentions, the decision makers at large brands have very little data about the materials they use, and the data they do have is usually fragmented, stored in spreadsheets and hidden away in multiple formats across the business.

Right now, there is no one platform that allows brands and their employees to capture, clean and structure their data and then analyse and benchmark themselves against the industry to make better decisions. Brands can do costly lifecycle analyses of individual products - but it can take months.

A dashboard for better products

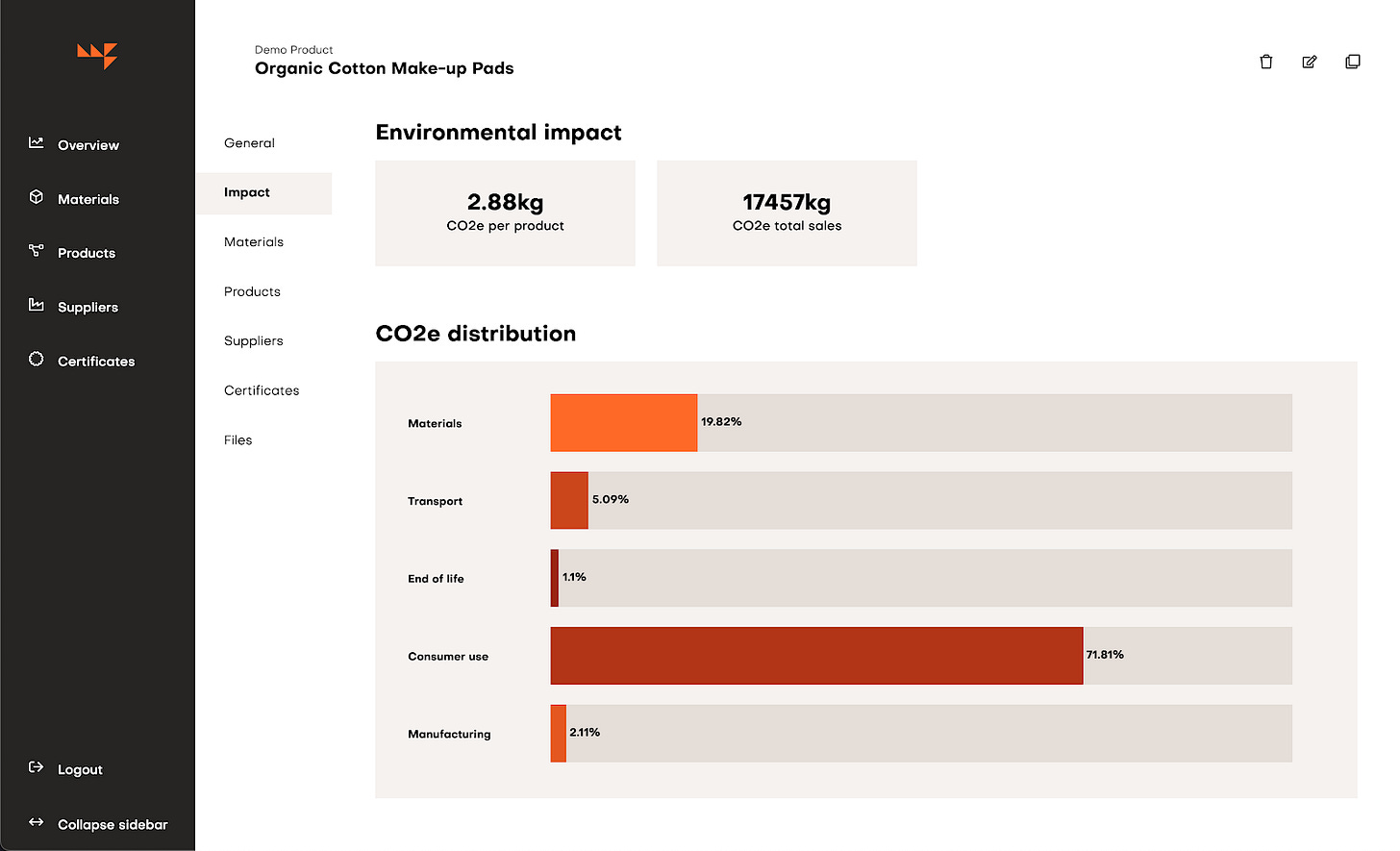

MadeFrom exists to make it easy for companies to manage the intelligence on the materials that they use in their products. We invested in MadeFrom last year, and MadeFrom has since built a material intelligence engine that combines data on cost, performance, sustainability, regulatory and marketability to inform material decisions. This allows companies to have an impact profile for their entire product range in minutes not months, helping them to make better products.

MadeFrom builds analytics for product impact - creating a dashboard of all the company’s products’ current materials, suppliers and standards - so they can see right away the impact they have at scale. This allows them to identify their weaknesses and benchmark against other products, and it also means that leadership teams can make strategic decisions and take simple steps to create a more sustainable product range.

Regulation is catching up too

Companies are beginning to look at the climate impact of their products, and regulations and pledges are coming in fast too. At COP26, 131 companies signed up to the “Fashion Charter for Climate Action” (drafted in 2018). Here they agreed to source 100% of their materials from a list of "priority materials" (with low climate impact) by 2030. The EU too will roll out their new material disclosure policy in Q1 2022, putting pressure on all brands to report on their data and materials. These are regulations that will simply accelerate the growing demand from both customers and employees.

Betting on the future of materials

We think ‘material optimisation’ is a huge opportunity. Any platform that is able to own material data as well as provide a benchmark on the industry overall will provide immense value. Once you have material data the opportunities for how to use it are endless. For example, it can be used to optimise the design process, product procurement, sustainability reporting as well as carbon offsetting. Companies working in this space will first attract low carbon ‘early adopters’ but will soon widen out, as all companies will need to be sustainable soon. MadeFrom are in a great position to own the market, having already analysed over a million products, creating 1,400 materials with full impact profiles on their dashboard. We are excited to back them.

Dom, the founder of MadeFrom, is perfectly suited to this challenge, with a background in materials and corporate sustainability, and having worked for years at IKEA as Entrepreneur in Residence before dedicating himself to helping companies create even better products.

MadeFrom have built their MVP with multiple paid customers and will be launching the new product next year. Better companies make better products, but in order to unlock low carbon product design we need better data. MadeFrom is helping unlock this data and allow for quick material analysis, ultimately creating a better suite of products, one material at a time.

💡 Hey! We’ve open-sourced our research for everyone to see. Check out our latest public Notion post on fashion supply chains here.