OK, we’ve figured out how to capture carbon, now what do we do with it?

Why we invested in Paebbl

💡 Interested to go deeper first? Read our deep dive on research on carbon storage here.

The quest to sequester

All hopes to limit global warming to 1.5°C now depend on carbon removal, as well as reducing emissions. We need to remove a phenomenal ten gigatonnes of CO2 every single year - doubling to twenty gigatonnes in 2050. So, how do we get there?

Building a Futurama-style city full of CO2-sucking machines seems like a redemptive solution, but it’s not that easy. After all, we have a very short timeframe to build the infrastructure and incentives, so we need to make smart choices about how to remove and store this carbon. After all, should we invest in technological solutions, or should we look more at nature-based solutions? Which solutions remove carbon the fastest? Which solutions store it for as long as possible, reducing any side effects and maximising the co-benefits? And who will finance all this?

Scaling nature

The answers are not straightforward. The carbon removal market is still relatively early, it was only 5 years ago when the first ever commercial CO2 Capture plant opened - and despite being the largest in the world it can capture only 4000 tonnes of the 10 gigatonnes of CO2 required a year. We need technical and natural solutions to continue to scale, but we also need to figure out how to permanently store carbon for millennia - so all our hard work trapping carbon doesn’t result in it being released back into the atmosphere.

There are promising solutions. You probably know that plants remove CO2, but did you know rocks remove CO2 too? More importantly - they also store it for an extraordinarily long time.

Carbon storage: solid as a rock

Carbon mineralisation is the process by which carbon dioxide becomes a solid - and it holds huge promise for long term carbon storage. To understand how this mineralisation works, it’s helpful to start in the ocean. Believe it or not, ocean creatures like clams and corals have been steadily playing their part to sequester carbon for millenia. Their shells are made from carbon - from a compound called calcium carbonate (otherwise known as limestone). You may have seen this limestone is other forms before too. For example, the UK’s White Cliffs of Dover are made from chalk - finely grained limestone once deposited in the ocean - and they too are storing carbon. Even as high up as the Alps and Himalayas you can find sea shells, as these very mountains were once at the bottom of the ocean. Mineralisation happens when dissolved rock material ends up in the ocean, those particles react with the CO2 in the water and combine to form solid calcium carbonate (limestone).

This process has been happily working for millions of years, but since the Industrial Revolution, emissions have risen and this once magical CO2-sucking solution now has a big challenge… it’s way too slow.

Accelerating mineralisation

This is where things get really interesting. We can expedite that cycle using modern technology, through heat and pressure. This involves crushing the rocks - exposing more reactive surface area - and then adding this material (silicate-rock) to a reactor where heat and pressure speeds up the CO2 uptake. The reaction itself actually generates energy that can also be used to reduce the energy demands of the process. The process traps CO2 into the crystal structure of minerals - and makes it part of the rocks - promising high permanence (read: long-term) carbon storage.

The best part? With mineralisation, there is an afterlife for carbon. We don’t need to banish carbon dioxide to the sea floor or hope it won’t be burnt down and released in forest fires. Instead, we can capture the carbon and - just like those clams did in the ocean - alchemize it, and turn it into something useful. We can use restored carbon in everyday materials, not only removing it from the atmosphere but helping decarbonise other industries.

Paebbl: having your carbon and treating it

Paebbl, who we invested in earlier this year, are on a mission to scale up mineralisation and put carbon dioxide to good use. They’re compressing the geological timescale to hours not years, and storing carbon at scale by turning it into useful industrial raw materials.

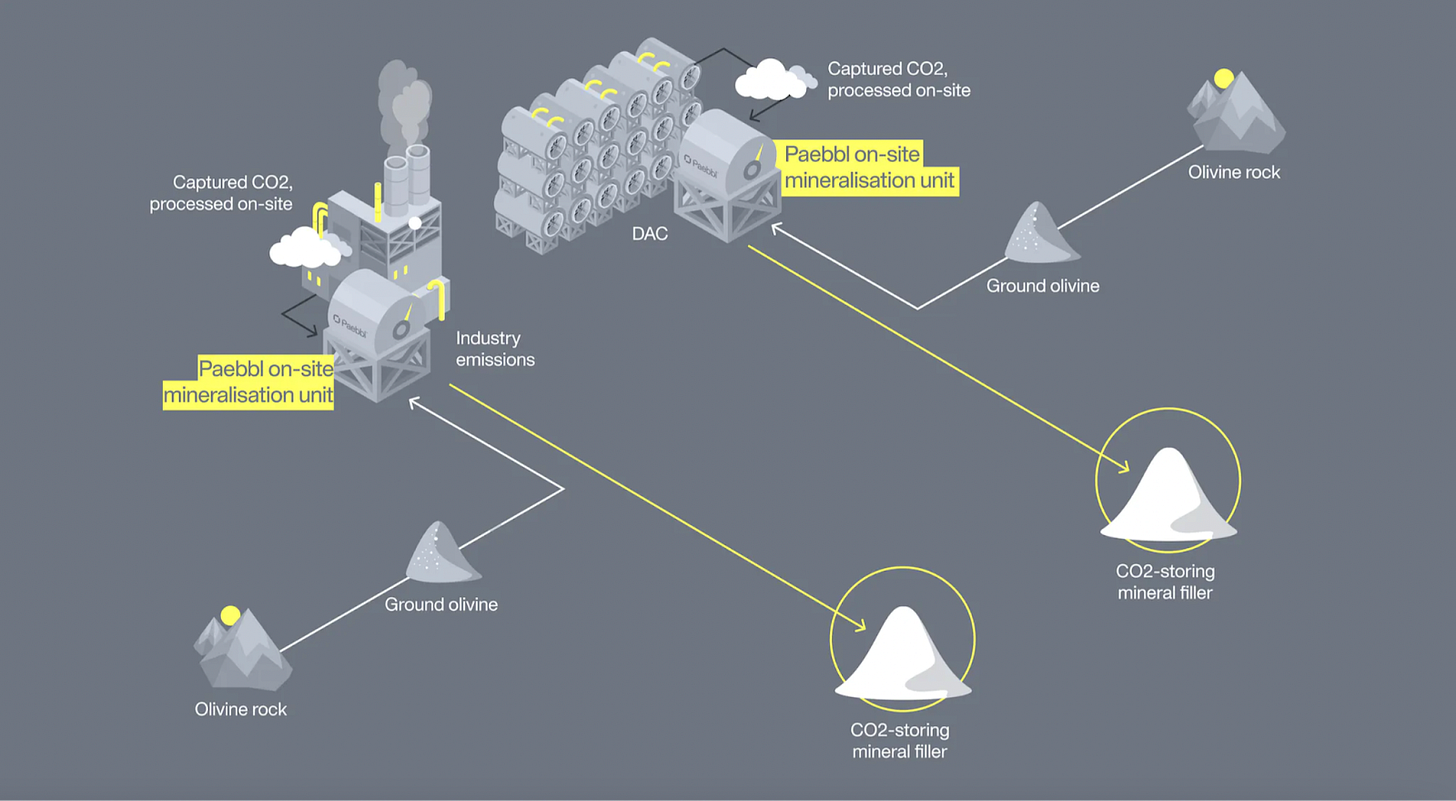

More specifically, Paebbl is building modular technology to be integrated into any carbon capture system - offering permanent CO2 storage and delivering a carbon negative, and climate positive, raw material.

Finding a use for climate positive materials

The raw material stream produced by Paebbl’s reactors is climate positive, with long term carbon storage. This is exciting - as producing a material made from stored CO2 can replace high-emissions materials, having a win-win climate impact. It can replace components in industrial products in global markets - like paper and cement. For example, lime and limestone is normally heavily used in the paper industry (and in this process, you’re also releasing CO2 trapped within the limestone). Replacing mined limestone with Paebbl’s CO2-storing materials can still maintain the same quality product - and reduce the emissions of the original industry.

Cement is another example. Cement production is currently responsible for 8% of global CO2 emissions and more than half of this comes from making "clinker," the binding agent in cement - typically also made by heating limestone. Clinker can be fully or partially replaced using CO2-enriched minerals and this substitution could displace up to 1.5 gigatonnes of CO2 per year (about 3% of global GHG emissions).

More financial incentives for carbon removal

Paebbl’s carbon-negative material also offers to create a new revenue stream that could fundamentally change the economics of carbon capture. After all, if we want to scale carbon removal we need it to be economically viable.

The voluntary carbon market has shown early demand for carbon removal. Earlier this year large tech companies like Stripe, Alphabet, Meta, and Shopify came together to launch Frontier Climate - a huge advance market commitment of almost US$1B to fund permanent carbon removal between 2022 and 2030. The market is growing but we need additional financial incentives to remove carbon from the atmosphere. Creating useful materials from the CO2 - with long-term storage - provides another revenue stream for carbon removal plants, all while providing new climate positive materials for industries that need to decarbonise their own processes.

Paebbl: the team to make it happen

We invested in Paebbl, alongside the Grantham Foundation and 2050, both because we are excited by the dual climate function of the technology and because of the incredible team to bring it to market. The technological process has already been run for years by Pol Knops - CTO and co-founder of Paebbl - in his company Green Minerals, and Pol was also involved in the key research publications of mineralisation. The other co-founders; Jane Walerud, Marta Sjögren and Andreas Saari, all have extensive commercial experience. Marta was previously a Partner at Northzone, Andreas was previously an investor and CEO of the tech conference Slush and Jane Walerud is an experienced serial entrepreneur, investor and chair of the board.

It is rare to find secure long-term carbon dioxide storage solutions, and it is even more rare to find applications where you can use the products and replace high-emission alternatives. It has potential to be a win-win for the climate crisis. Instead of banishing carbon, we can transmute it, alchemise the damage of carbon dioxide and turn it into useful things that the world needs. It can both remove and reduce emissions. We are excited to join Paebbl on the journey ahead.

Paebbl will be hiring soon!

Interested to go deeper? Read our Research Notion on carbon storage here.